Welcome to the AGISEN website

Measurement Challege

Combustion and engine research are key to the development of the next generation, fuel efficient automobiles. Unfortunately, in-cylinder, spectroscopic measurements are conducted using transparent cylinder linings in single-engined test beds. The results obtained do not usually equate well with fully-encased metal engines. The challenge here was to develop a metal insert, (OPAL - optical access layer), 5mm thick that would sit between the engine block and the head and provide a mechanism for introducing optical fibres into the engine. These fibres were arranged in transmit-receive pairs, producing collimated beam paths across the cyclinder, and used to facilitate tomographic measurement of the engine’s combustion process.

Solution

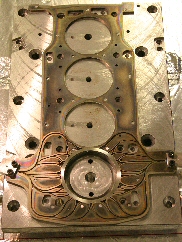

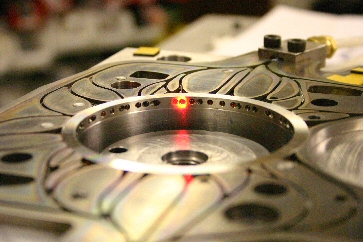

As the tomographic design criteria called for a minimum of 27 transmit-receive channels it was necessary that suitable fibre handling and protection strategies were developed. Key to this was the development of a simple, self-sealing optical collimation component that would perform in this extreme environment. Image 1 shows the developed component, consisting of a specially aligned and moulded ball lens collimator.

The metal gasket itself can be seen in the middle image. This together with a mechanically stable optical ring assembly (right most image) makes up the main components of the system. The collimators were pre-aligned into the ring which was then press fitted into the gasket. The fibres were feed along the carefully shaped channels an encased using a special epoxy.

If you wish to find out more about this application of optical fibre sensing please contact Dr. Tim Litt.